Cylinder relief valve

Cylinder relief valve

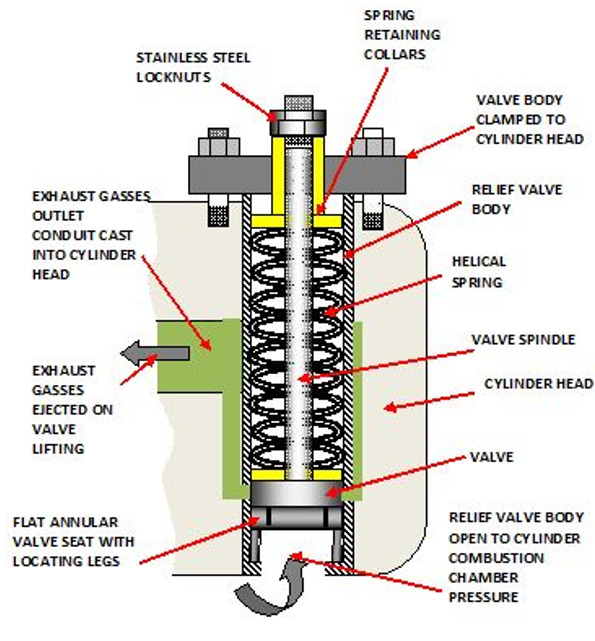

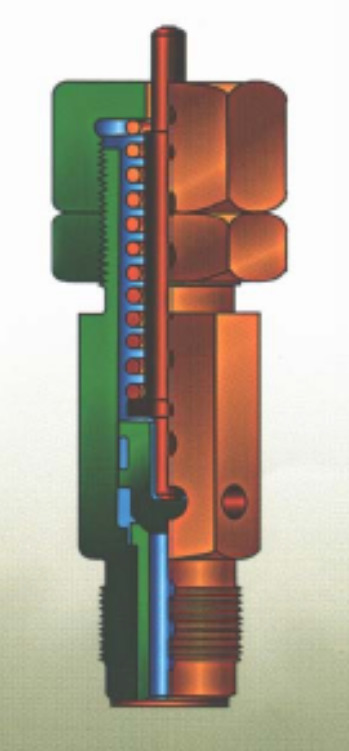

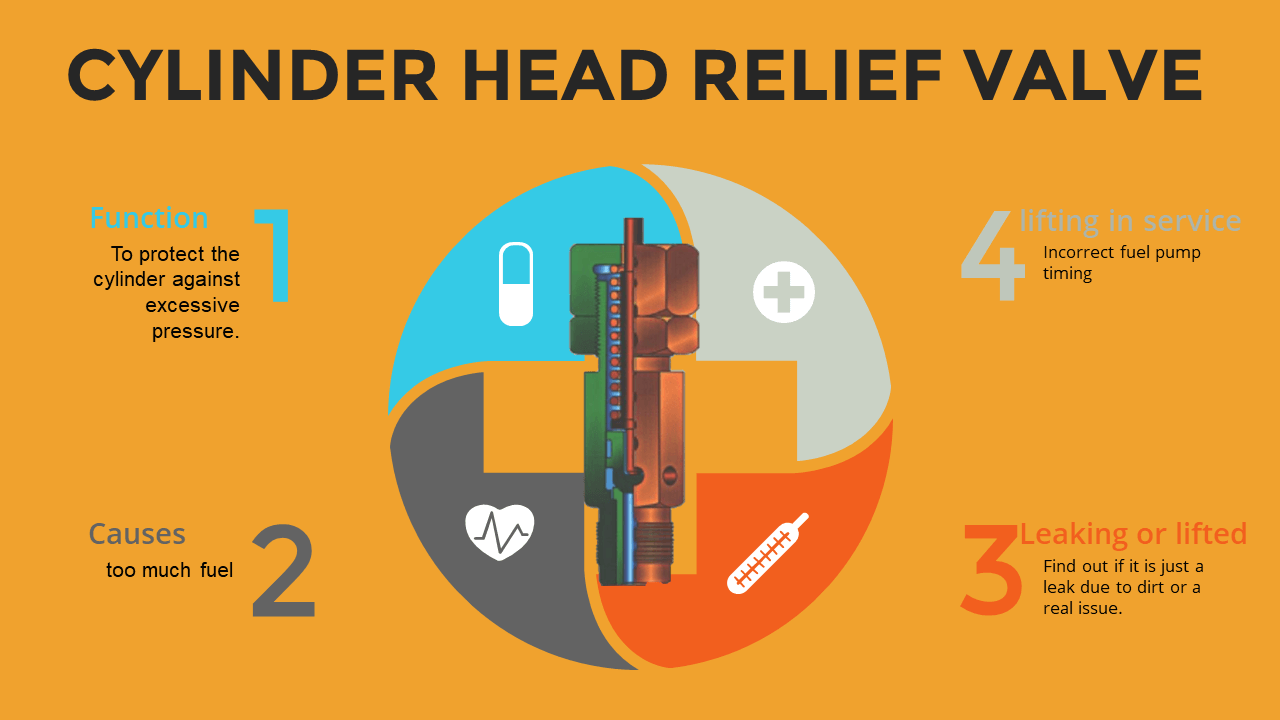

Function

>> To protect the cylinder against excessive pressure. The blow-off pressure should be adjusted 20 to 30% above the normal working load.

>> Main purpose is to lift when over pressure occurs in the combustion area; the resultant combustion gas being expelled to a through a flang-ed pipe to deck.

Causes of Relief valve Opening

1) Manoeuvring handle being moved too far causing fuel injection excessive. When too much fuel is supplied by the engineer when on starting the engine.

2) If air is being used to stop engine in “emergency stop” situation.

3) Incorrect fuels pump timing causing over-fueling.

4) Running engine full astern for a prolonged period, in this case the bridge should be informed that astern running is at its limit.

5) Incorrect adjustment of fuel valve opening pressure (low).

4) Incorrect governor setting causing over-fuelling.

5) Fuel oils remain on top of the piston owing to:

A. Improper priming operation

B. Fuel valve renewal period

C. Fuel oil injected in previous fail-start operation still remaining on piston top.

Causes of lifting in service

1. Incorrect fuel pump timing, Faulty fuel pump or incorrectly set fuel injector delivering excessive fuel.

2. Air start valve stuck open or wrongly timed.

3. Incorrect camshaft timing, chain breakage or Governor Fault especially in heavy seas.

4. Badly leaking fuel injector; through loose nozzle or enlarged injection holes.

5. Water leaking into the combustion chamber.

6. Scavenge fire.

What to do if cylinder head relief valve is leaking or lifted?

Temporary measures

>> Either leaking or lifting of relief valve, both should be considered as a serious issue and should be investigated. If the ship is maneuvering and the engine cant be stopped, below temporary measures can be taken;

1. Rotate the spindle on its seat until leakage stops, in most cases dirt accumulated on the seat can be driven off.

2. Gentle knock on the spindle also can help stop the leak.

3. Inform bridge about the issue and ask them to reduce stops & starts.

Permanent solution to a leaky relief valve

>> Check for unit specific parameters such as exhaust temperature, scavenge pressure and temperature, CW outlet temp etc, if you have any reason to suspect abnormalities investigate the cause further.

>> If all parameters appear normal, stop the engine in a safe spot, replace the relief valve

>> Take indicator card and ensure the peak pressure is within limits and other parameters are satisfactory.