Metal locking crack repair process

What is Metal-locking?

Metal locking crack repair process – Metal-lock or metal stitching is a method of repairing fractures to castings, onsite without the use of heat. It involves sinking Metal-lock keys, perpendicular to a fracture. The fracture is then sealed and held rigid by Metal-lace studs. The result is a repair that is sealed tight and flush with the surface, recreating much of its original strength.

What types of repairs are carried out by metal-locking?

>> As a cold repair process, metal stitching is applicable where heat should not be used, and in situations where the material cannot be successfully repaired by welding.

>> Large structure: Such as engine blocks, ‘A’ frame cracks, Auxiliaries structure which can’t be removed out for repairs easily are repaired using ML process.

>> Material Characteristics: Where welding due to heat would introduce thermal stresses into the base metal, and also changes the grain structure of the metal crystals – altering the characteristics and the strength of that part of the equipment, ML is used.

>> Alignment: The metal stitching repair process maintains alignment of original surfaces, since the lack of heat during the repair produces no distortion of the completed repair.

>> Dampens stress: Metal stitching dampens and absorbs compression stresses; providing a good ‘expansion joint’ for castings subject to thermal stresses.

>> Pressurized interface: Where the repair involved a pressurized interface, the repair process has the ability to seal the join.

Procedure of Metal locking crack repair process.

Metal locking procedure is done in 5 main steps

1. Examination and preparation

– After close inspection the metal is lined as such the cracks are held together using pressure clamps.

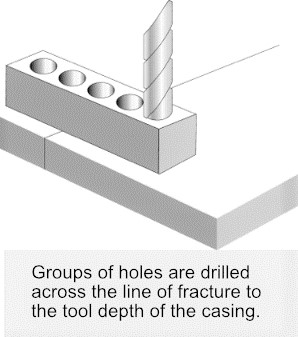

2. Drilling & Fitting

– Using a drilling template, the holes are drilled perpendicular to the crack to the depth of castings.

– Using a drilling template, the holes are drilled perpendicular to the crack to the depth of castings.

– The length of holes are adjusted to the extent of crack.

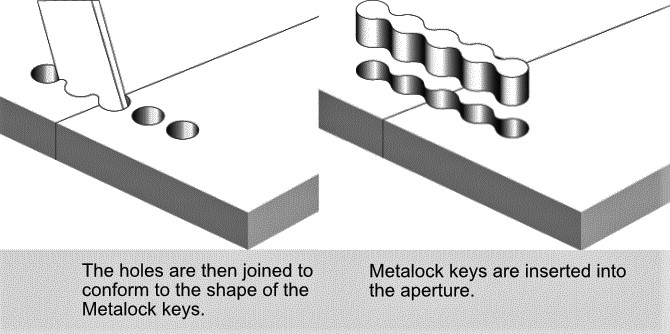

3. Connecting the holes and inserting the metal lock keys

– The holes are connected in the middle matching the shape of the keys.

– The holes are connected in the middle matching the shape of the keys.

– The keys are inserted and hammered to the complete depth. The keys are of slightly larger in size than the holes.

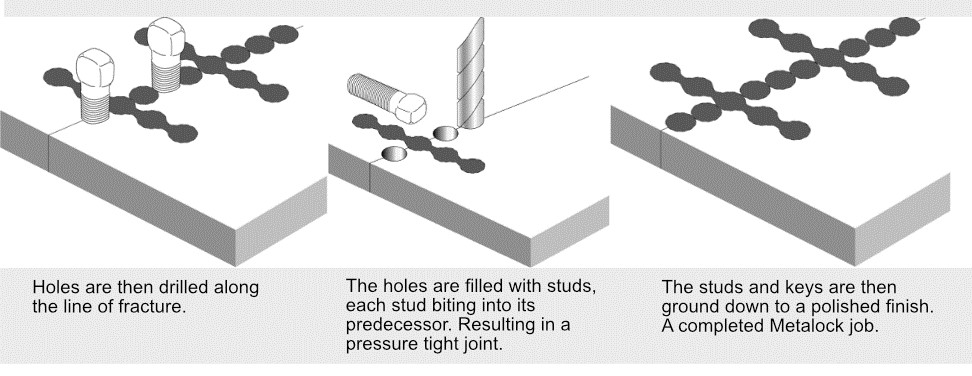

4. Applying pressure tight joint

– Holes are drilled along the line of fracture.

– Holes are drilled along the line of fracture.

– The holes are then filled with studs, each stud biting into its predecessor which results in pressure tight joint of the piece.

5. Finishing

– The surface is completely ground off to give smooth finish and then the surface is cleaned and painted if it’s a painted surface.

For more information please check : https://www.metalockengineering.com/en/typical-repairs/metal-stitching/

Respected SIR,

thanks so much for this solved answers, which would be very much useful for my upcoming MEO CL II examinations.

I am highly grateful to you,

I am conveying my best regards to you,

yours sincerely

JAYANTA MUKHERJEE