Rocking test of Deck Crane

Video credits : www.youtube.com

What is Rocking test of Deck Crane?

– Rocking test of deck crane is carried out to ascertain the wear down of the sleeve bearing of the deck cranes by measuring the play (relative movement) between the inner and outer bearing race. This measurement indicates the rate of wear.

– Usually the wear down is also identified by analyzing the grease sample taken from the bearing housing.

– The Rocking Test needs to be carried out according to manufacturer recommendation.

– No loads shall be to the crane hook, positions below are usually marked and used always as a datum reference.

– Measurements are typically taken in four positions on the slew bearing, with the jib pointing:

- Extended towards forward

- Extended Towards aft

- Hard to port side

- Hard to starboard

-‘Rocking tests’ are carried out every six months and that the results are recorded and monitored in order to ensure the wear tolerances remain within the limits.

Procedure of rocking test of deck crane

Preparation

– The ship is adjusted to have least possible trim, preferably on even keel.

– Bad weather / Windy situations are avoided.

– No cargo or bunkering operation is permitted.

– Crane hook is free of any load.

– A properly working and calibrated dial gauge is used and not a Vernier caliper.

Procedure

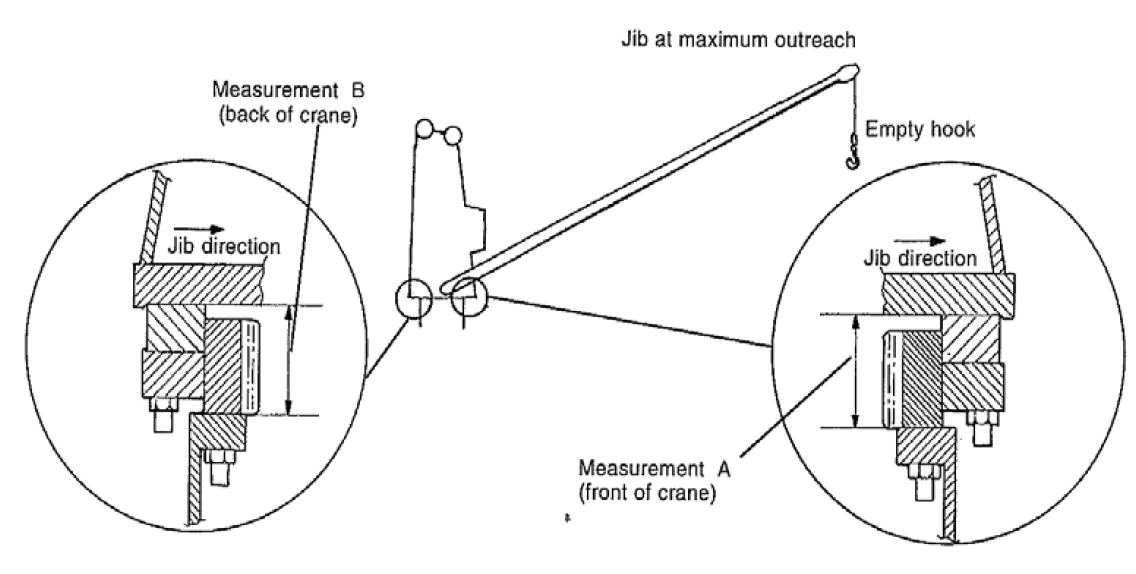

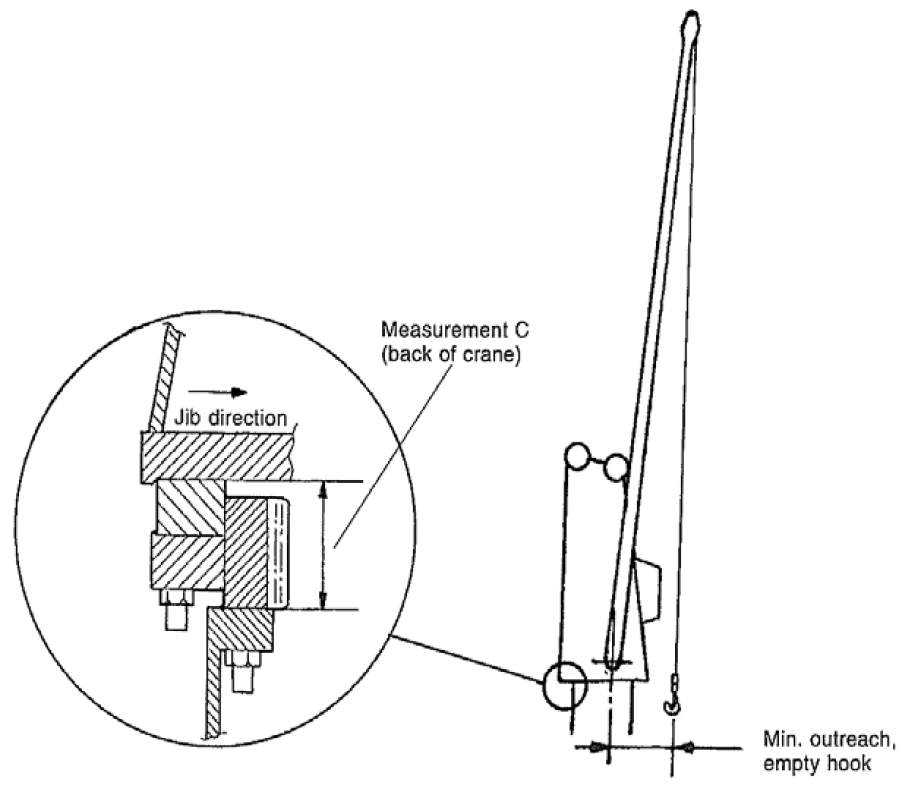

– Usual rocking test reference points usually two of them on the front and rear bottom plate of the crane. These points are always used for such tests.

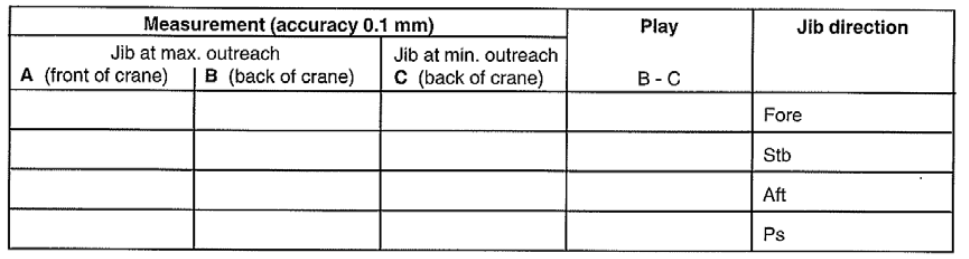

Tabulation and fault finding procedure.

rocking test measurements logging table

– Measurements are recorded with an accuracy of 0.1mm.

– If measurement B – measurement C = 0 or negative then the measurement is wrong, please re check.

– If measurement B – measurement A = 7 or more then the crane must be stopped and shall not be used until the bearing replacement is taken and tested & surveyed again.

– Maximum allowed play

+ For roller bearings = 1.5 mm

+ For ball bearings = 3.0 mm.

– Cranes which are particularly at risk are those with single ball race slew bearings. Cranes fitted with this type of slew bearing must have rocking tests carried out, in accordance with manufacturer’s instructions, to determine that the amount of wear in the bearing races is within permitted limits.

What is the action taken if deviation is out of limit?

– Measurements are recorded every 6 months and if wear rate is seen increasing, the greasing is to be increased. While adding grease, the bearings should be rotated to spread the grease throughout. Pump in until old grease squeeze past the seal (Purging)

– Purged grease carries contaminants out of the bearing. Rubbing between your finger and grit or metal chips is felt, it indicates a bearing wear.

– Grease tends to dry out over long periods of time, allowing condensation to form within a bearing. It is avoided by introducing grease at least every six months, even when the crane is idle.

– If wear is out of limit, then the bearing is to be replaced, if the life time of the wear is pre-mature then the reason for the same needs to be investigated.

– If the wear is close or on the limits, operating the cranes less than the max SWL and hoisting with the extended jib is to be restricted. Operate the jib within less outreach.

Please visit dieselduck forum for more infomation http://www.dieselduck.info/forum/viewtopic.php?t=1603

Thank you for very much it is very helpful for us.

Adrian, Glad it was useful to you. Please do visit us for more such articles.

Thanks. Thank you for very much it is very helpful for us.

Thank you for very much it is very helpful for us.

in the theory part you mentioned use dialgauge not use vernier caliper but in video u used vernier

Thank you very much. Very helpful.

Are you sure that if measurement B – measurement A = 7 or more then the crane must be stopped?

Is it possible to provide reference for this information?

Thanks

Dimitrios Sois

wrong info…. if B-A is more than 7mm then it means that the fasteners are not tightened properly… and with the from the procedure you have illustrated, a Sliding Vernier Caliper or a Depth Gauge should be used and not a dial gauge. Please follow the procedures and method mentioned in the manual of your cargo cranes. I am quite familiar with the procedure that you mentioned here and it came from one of the makers of cargo crane yet you are changing the tool to use. Dial Gauge method has been changed by this maker long ago….