A comparison study of OTTO & Diesel cycles and suitability of natural gas

Marine diesel and natural gas engines: a comparison of cycles and suitability of natural gas

Marine diesel engines have traditionally relied on the diesel cycle for combustion. However, with the increasing use of natural gas as a marine fuel, the Otto cycle is also being employed in some engines. This report aims to explain the difference between the diesel cycle and the Otto cycle, and to elaborate on the suitability of natural gas as a fuel in marine engines.

Diesel Cycle vs. Otto Cycle

Both the diesel cycle and the Otto cycle are thermodynamic cycles that describe the process of converting heat energy into mechanical work in internal combustion engines. However, they differ in their methods of heat addition and ignition. In addition to these two cycles, a dual cycle (a combination of Otto and Diesel cycles) is a more realistic model for natural gas engines, as it allows for adjustments in the heat transfer process to better approximate real-world engine operation1.

Diesel Cycle

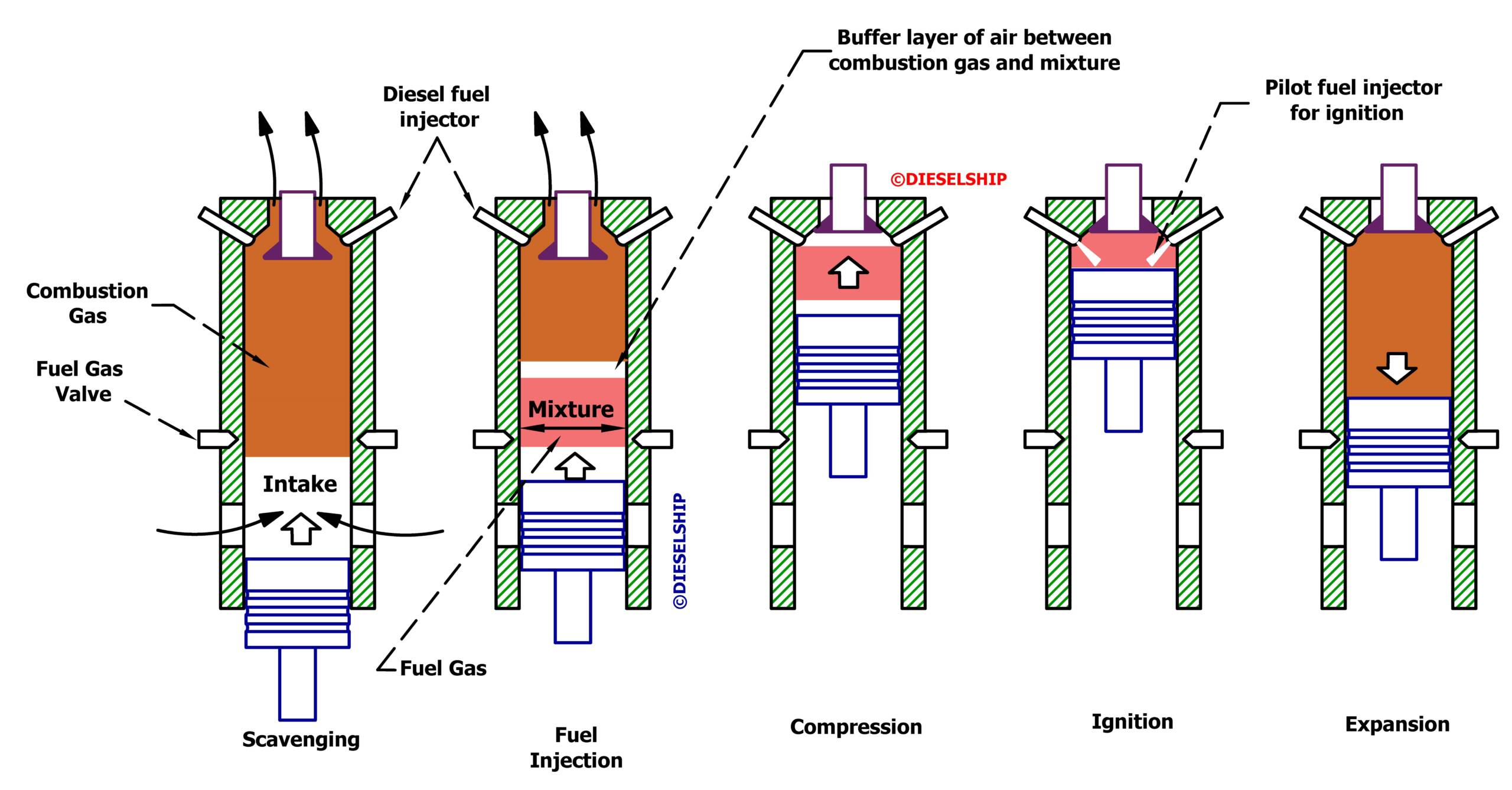

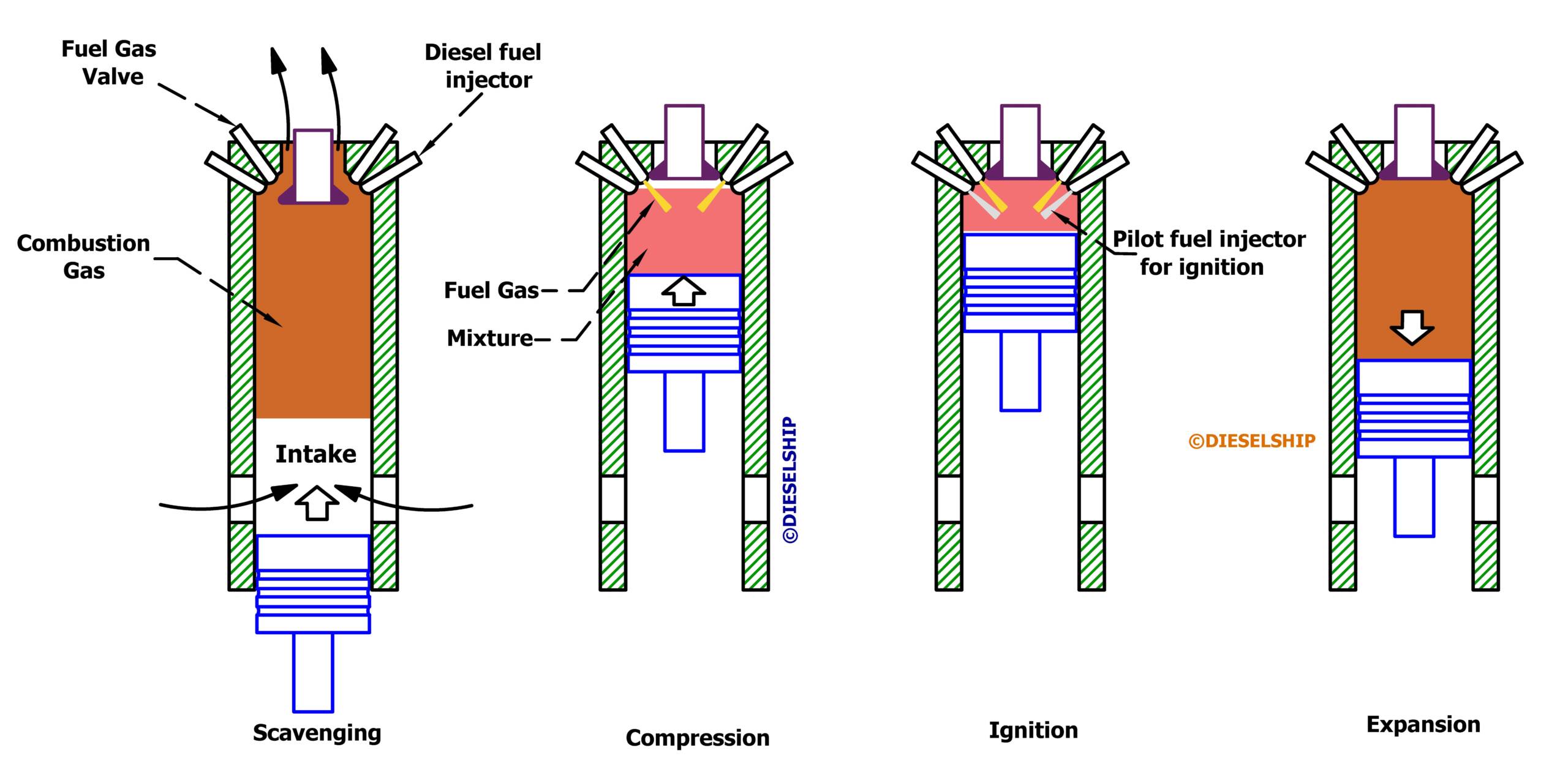

The diesel cycle is a constant pressure cycle, meaning that the heat addition process occurs at a constant pressure. In a diesel engine, air is compressed to a high temperature and pressure. Fuel is then injected into the combustion chamber, where it ignites spontaneously due to the high temperature of the compressed air. This process is known as compression ignition. The key characteristics of the diesel cycle are:

- High compression ratio: Diesel engines have a higher compression ratio compared to Otto cycle engines, typically ranging from 14:1 to 25:1. This higher compression ratio leads to higher thermal efficiency2.

- Compression ignition: The fuel is ignited by the high temperature of the compressed air, eliminating the need for a spark plug2.

- Constant pressure heat addition: Heat is added to the system at a constant pressure during the combustion process2.

- Fuel injection: Fuel is injected directly into the combustion chamber3.

Otto Cycle

The Otto cycle, on the other hand, is a constant volume cycle, where the heat addition process occurs at a constant volume. In an Otto cycle engine, a mixture of air and fuel is drawn into the cylinder and compressed. The compressed mixture is then ignited by a spark plug, causing a rapid increase in pressure and temperature. This process is known as spark ignition. The key characteristics of the Otto cycle are:

- Lower compression ratio: Otto cycle engines have a lower compression ratio compared to diesel engines, typically ranging from 8:1 to 12:12.

- Spark ignition: A spark plug is used to ignite the compressed air-fuel mixture3.

- Constant volume heat addition: Heat is added to the system at a constant volume during the combustion process2.

- Carburetor: A carburetor is used to mix air and fuel before it enters the cylinder3.

The following table summarizes the key differences between the diesel cycle and the Otto cycle:

| Feature | Diesel Cycle | Otto Cycle |

| Thermal Efficiency | High | Low |

| Compression Ratio | High (14:1 to 25:1) | Low (8:1 to 12:1) |

| Heat Addition | Constant pressure | Constant volume |

| Ignition | Compression ignition | Spark ignition |

| Fuel | Diesel | Petrol |

| Fuel Entry | Fuel injector | Carburetor |

| Working Cycle | Constant pressure cycle | Constant volume cycle |

Natural Gas as a Marine Fuel

The maritime industry is increasingly adopting liquefied natural gas (LNG) as a marine fuel to address economic and environmental concerns. This shift is evident in the growing number of LNG-fuelled vessels, which now represent 6% of the global fleet by deadweight tonnage (DWT)4. This section explores the suitability of natural gas as a marine fuel, examining its application in various engine types, its environmental and economic impacts, and the technical challenges associated with its use.

Suitability of Natural Gas in Marine Engines

Natural gas can be used in marine engines in two primary ways:

- Dual-fuel engines: These engines can operate on both natural gas and traditional marine fuels like diesel or heavy fuel oil. Wärtsilä, a leading manufacturer of marine engines, has developed dual-fuel engines that can switch between natural gas and liquid fuel while running5. This flexibility allows ships to comply with emission regulations in different regions and optimize fuel consumption based on availability and cost6.

While dual-fuel engines offer flexibility, some applications benefit from dedicated pure gas engines.

- Pure gas engines: These engines are designed to operate solely on natural gas. Wärtsilä’s 31SG pure gas engine is an example of this technology. Pure gas engines offer the lowest total cost of ownership and the lowest environmental footprint for operations with a secured gas supply, such as fixed short routes with available gas bunkering infrastructure7.

The different types of natural gas engines and their suitability for various applications are summarized in the following table:

| Engine Type | Description | Advantages | Disadvantages | Suitable Applications |

| Dual-fuel engines | Can operate on both natural gas (LNG) and traditional marine fuels (diesel or HFO). | Flexibility in fuel choice, compliance with varying emission regulations, optimized fuel consumption. | Higher initial cost compared to traditional engines, potential for methane slip. | Ships operating in regions with varying emission regulations, vessels with varying fuel availability. |

| Pure gas engines | Designed to operate solely on natural gas (LNG). | Lowest total cost of ownership, lowest environmental footprint. | Limited fuel flexibility, requires reliable gas bunkering infrastructure. | Fixed short routes with secured gas supply, environmentally sensitive areas. |

Environmental Impact

Natural gas has a cleaner burning profile compared to diesel fuel, resulting in significant reductions in emissions of harmful pollutants. Studies have shown that using natural gas in marine engines can reduce SOx emissions by as much as 99%, NOx emissions by up to 85%, and largely eliminate particulate matter from ship exhaust8. These reductions are crucial for complying with increasingly stringent environmental regulations, such as the International Maritime Organization’s (IMO) Tier III regulations. Wärtsilä’s dual-fuel engines, for example, are compliant with IMO Tier III regulations when operating on gas and IMO Tier II regulations when using liquid fuel oil5.

Furthermore, LNG-powered vessels can eliminate the need for expensive exhaust gas cleaning systems while still meeting emission regulations5. This represents a significant economic and environmental advantage, as it reduces both capital expenditure and operational costs associated with emissions compliance.

Switching from marine diesel oil to natural gas can lead to substantial reductions in various emissions. One study illustrated that NOx, SOx, particulate matter, and CO2 emissions were reduced by 72%, 91%, 85%, and 10%, respectively9. These findings highlight the potential of natural gas to significantly improve the environmental performance of the shipping industry.

However, it’s important to consider the potential for methane slip, which is the unintentional release of unburned methane from the engine. Methane is a potent greenhouse gas, and even small amounts of methane slip can offset the climate benefits of using natural gas10.

Economic Impact

The marine engine market is projected to experience significant growth in the coming years, with a market value of US\$12.6 billion in 2023 and a forecasted revenue of US\$18.5 billion by 2033, growing at a strong compound annual growth rate (CAGR) of 3.9% from 2024 to 203311. Within this growing market, natural gas engines offer compelling economic benefits. The price of natural gas is often lower and more stable compared to traditional marine fuels like diesel12. This can result in significant fuel cost savings for ship operators. Additionally, natural gas engines generally require less maintenance than diesel engines, further reducing operating costs13.

Technical Challenges

While natural gas offers several advantages as a marine fuel, there are also technical challenges associated with its use. Some of the key challenges include:

- Fuel storage: Natural gas needs to be stored in liquid form (LNG) at cryogenic temperatures (-160°C). This requires specialized storage tanks with features like heavy insulation and temperature control to maintain the LNG in a liquid state14. These tanks are typically either spherical (Moss type) or rectangular with a stainless-steel membrane (Membrane type)15. Membrane tankers are more common due to their smaller size for the same LNG capacity, but they tend to have higher boil-off gas (BOG) rates compared to Moss type carriers15. This BOG, however, can be efficiently utilized in steam turbine systems for propulsion or auxiliary power generation15.

- Methane slip: As mentioned earlier, methane slip is a concern with natural gas engines. Engine manufacturers are continuously working to improve combustion efficiency and minimize methane slip10.

- Variable gas quality: The quality of natural gas can vary depending on the source and processing methods. This variability, particularly in the methane number, can affect engine performance and emissions16. Engine designs need to be robust enough to handle these variations, with features like advanced knock (pre-ignition) control systems to ensure stable and efficient combustion16.

- Knocking combustion: Natural gas engines can be susceptible to knocking combustion, which is the uncontrolled ignition of the fuel-air mixture. This can damage the engine and reduce efficiency17. Maintaining a stable fuel-air mixture, especially under varying engine loads, is crucial to prevent knocking and misfiring17. This requires precise control over fuel injection and air intake, which can be challenging in marine applications where engine loads fluctuate frequently.

Conclusion

The use of natural gas as a marine fuel is a growing trend driven by environmental regulations and economic considerations. The diesel cycle and the Otto cycle, along with the more realistic dual cycle, provide the thermodynamic frameworks for utilizing natural gas in marine engines. The choice of engine cycle depends on factors such as the type of engine, operating conditions, and desired efficiency.

Natural gas offers significant potential for reducing emissions and improving fuel efficiency in the marine industry. Studies have shown substantial reductions in NOx, SOx, particulate matter, and CO2 emissions when switching from marine diesel oil to natural gas9. Moreover, LNG-powered vessels can eliminate the need for expensive exhaust gas cleaning systems5. Economically, natural gas often has a lower and more stable price compared to traditional marine fuels, leading to cost savings for ship operators12.

However, it’s crucial to address the technical challenges associated with natural gas use. These include the need for specialized storage tanks and handling systems14 the potential for methane slip10 the variability in gas quality16 and the risk of knocking combustion17. Overcoming these challenges through ongoing research and development of advanced engine technologies will be essential to fully realize the environmental and economic benefits of natural gas in the marine industry.

Works cited

- Difference between Otto and Diesel cycles, accessed December 19, 2024, https://users.encs.concordia.ca/~kadem/MECH%20351/NOTES/7_Diesel_%20cycle.pdf

- Otto and Diesel cycles | Thermodynamics Class Notes – Fiveable, accessed December 19, 2024, https://library.fiveable.me/thermodynamics/unit-13/otto-diesel-cycles/study-guide/U5S0NTc2iVgHLIa5

- Diesel cycle, Otto cycle and Dual Cycle – Merchant Navy Decoded, accessed December 19, 2024, https://www.merchantnavydecoded.com/diesel-cycle-otto-cycle-and-dual-cycle/

- LNG-fuelled vessels accelerate to 6% of the global fleet, accessed December 19, 2024, https://sea-lng.org/2024/10/lng-fuelled-vessels-accelerate-to-6-of-the-global-fleet/

- Wärtsilä: Using Natural Gas as Fuel in Marine Engines – HBM, accessed December 19, 2024, https://www.hbm.com/tw/6518/waertsilae-using-natural-gas-as-fuel-in-marine-engines/

- LNG as fuel for ships: Expert answers to 17 important questions – Wärtsilä, accessed December 19, 2024, https://www.wartsila.com/insights/article/lng-fuel-for-thought-in-our-deep-dive-q-a

- Wärtsilä 31SG marine spark gas engine, accessed December 19, 2024, https://www.wartsila.com/marine/products/engines-and-generating-sets/pure-gas-engines/wartsila-31sg

- What Is LNG Gas, and What Are LNG-Powered Cruise Ships? – Cruise Critic, accessed December 19, 2024, https://www.cruisecritic.com/articles/what-is-lng-gas-and-what-are-lng-powered-cruise-ships

- (PDF) Environmental and economical benefits of changing from marine diesel oil to natural-gas fuel for short-voyage high-power passenger ships – ResearchGate, accessed December 19, 2024, https://www.researchgate.net/publication/245387227_Environmental_and_economical_benefits_of_changing_from_marine_diesel_oil_to_natural-gas_fuel_for_short-voyage_high-power_passenger_ships

- Liquefied natural gas (LNG) – Transport & Environment, accessed December 19, 2024, https://www.transportenvironment.org/topics/ships/lng

- Marine Engines Market Set to Hit USD 18.5 billion by 2033, – GlobeNewswire, accessed December 19, 2024, https://www.globenewswire.com/news-release/2024/02/19/2831234/0/en/Marine-Engines-Market-Set-to-Hit-USD-18-5-billion-by-2033-Riding-on-a-Strong-3-9-CAGR-Market-us.html

- Evaluation of Methane Emissions Originating from LNG Ships Based on the Measurements at a Remote Marine Station – ACS Publications, accessed December 19, 2024, https://pubs.acs.org/doi/10.1021/acs.est.1c03293

- Economic benefits of natural gas engines – Cummins, accessed December 19, 2024, https://www.cummins.com/news/2022/06/03/economic-benefits-natural-gas-engines

- What is an LNG ship? – Clarksons, accessed December 19, 2024, https://www.clarksons.com/glossary/what-is-an-lng-ship/

- Marine LNG Engine – Wikipedia, accessed December 19, 2024, https://en.wikipedia.org/wiki/Marine_LNG_Engine

- Efficiency challenges for gas engines – Infineum Insight, accessed December 19, 2024, https://www.infineuminsight.com/en-gb/articles/efficiency-challenges-for-gas-engines/

- bibliotekanauki.pl, accessed December 19, 2024, https://bibliotekanauki.pl/articles/242119.pdf

- Dual-Fuel Marine Engine (Highly Reliable Environmentally Friendly Engine)|YANMAR Technical Review|Technology|About Us, accessed December 19, 2024, https://www.yanmar.com/global/about/technology/technical_review/2015/0727_2.html

I am a lecturer for conducting the engine cadet(STCW) program. Kindly advise how I could use your notes or books related to Engine construction ..etc related to EX Motor or EK General

We are providing solution only for Class 1,2,4 MEO CoC exams.