Various technologies used on oil content monitoring equipment

Various technologies used on oil content monitoring equipment

>> This article deals with the systems designed to monitor water discharged from vessels including bilge water separators, ODME equipment on tankers and exhaust scrubbing systems.

>> Other shipboard systems that may discharge to the sea and warrant monitoring – black and grey water and ballast water can also prevail of the same technology but applied in different applications.

Technologies used to detect the presence of oil in water

>> A variety of technologies are used to detect the presence of oil in water most of which are optical-based.

>> Their effectiveness will vary depending upon a number of factors such as the oil content of the water, the presence of solids such as rust, chemical contaminants and the turbidity of the water. Some systems cope better than others with one or more of these conditions but since the composition and quantity of bilge is never a constant, an element of chance is involved in selecting the most suitable.

Scattered Light

>> This technology is a popular choice for OCMs on ships because of its relatively low cost and is unaffected by watercolour.

>> This technology is a popular choice for OCMs on ships because of its relatively low cost and is unaffected by watercolour.

>> On the downside, excessive solids can affect readings and the systems must also be calibrated to specific oil types which can lead to deviations if the oil varies.

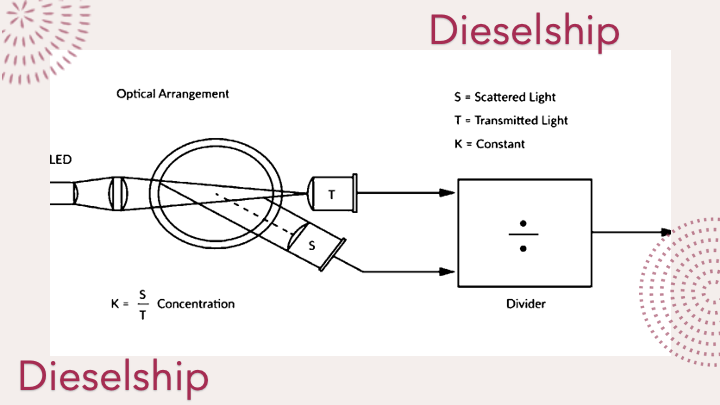

>> These monitors measure the intensity of light as it passes through water to indicate oil concentration. Oil particles present in the sample water will scatter (or ‘refract’) light in correlation to the levels of oil in water: the higher the oil content, the more light is scattered.

>> Receivers measure the amount of light scattered, from which the concentration of oil in the water can be determined. Scattered wavelength technologies transmit a single wavelength of light such as ultraviolet, infrared or white light with various filters.

>> Each wavelength has its advantages. Infrared light, for example, provides stable measurements across a wide range of temperatures. Receivers can be placed all around the optical path.

>> Solids will also scatter light, but their irregular shapes do not refract light in the same way as oil’s spherical molecules. Using multiple angles of sensors highlights the shape of the molecules and enable solids to be discounted.

Challenge with this technology

>> One challenge associated with scattered light measurements is the phenomenon known as ‘fall-off’.

>> Scattering of light peaks at around 100-150 ppm of oil, after which the concentration of oil is so great that it absorbs much of the light transmitted and the proportion of scattered light appears to fall. The level of fall-off is determined by the configuration of the measuring cell as well as the light wavelength and angle at which scattered light is measured.

>> If not accounted for, falloff can lead to disastrously misleading readings of oil concentration.

>> Another potential source of inaccuracy is the degradation of the light source over time. This will cause a lower level of light to be transmitted and received. If not accommodated, this can lead to inaccurate results as lower scattered light is recorded. In the first instance, a feedback circuit should monitor the power to the light source to keep it constant. A further, more reliable way of preventing the challenges caused by a degrading light source is to measure not only the scattered light received but also the amount of light transmitted.

Absorbance

>> Not a common choice for shipboard systems due to high cost but they are more accurate approaching laboratory standards of accuracy.

>> Absorbance measurement technologies make use of the fact that different particles absorb light of different wavelengths. Hydrocarbons absorb energy at a specific wavelength (3.4μm) and the amount of that wavelength energy absorbed is proportional to the level of hydrocarbons in a sample.

>> By measuring the amount of energy of specific wavelengths absorbed, the concentration of various oils and solids can be determined. One of the major advantages of using absorbance is that it can be used in dirty water including water containing oil-field chemicals. But measuring fluorescence with UV light can lead to false positives in dirty water. Measuring absorbed light at the right wavelengths reduces this risk.

Fluorescence

>> Is used in some OCMs for bilge water and is also a reliable technology for scrubber washwater monitoring. Fluorescence is an accurate technique for detecting oil in water.

>> A straight beam of ultraviolet light at a known wavelength is directed into a glass tube filled with the sample. When oil droplets are excited by ultraviolet light, they will emit light at a different wavelength. This is known as fluorescence light.

>> Each oil molecule has a specific fluorescence wavelength light. In this way, the oil’s presence can be accurately detected. As each species of oil reacts to different light wavelengths, using a single wavelength is ideal in applications dealing with a single, known species of oil.

>> However multiple types of oil and contaminants can lead to inaccurate readings, as they can fluoresce in the same way as the oil being measured. This is particularly true in oilfield applications, where both oil-coated solids and other chemicals can lead to false positives.

Microscopy

>> This is a good system for measuring oil content in bilge water and as it also detects gas bubbles present it is also useful for scrubber wash water monitoring from both SOx and NOx from EGR systems.

>> This is a good system for measuring oil content in bilge water and as it also detects gas bubbles present it is also useful for scrubber wash water monitoring from both SOx and NOx from EGR systems.

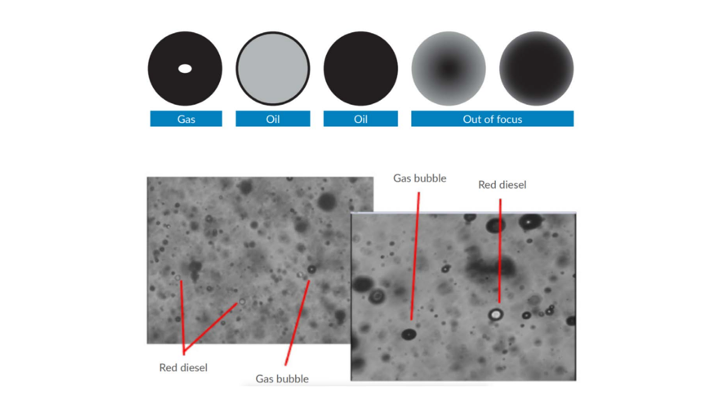

>> Microscopy is the determination of oil concentration by measuring droplet size through image processing and recognition software. A high-speed camera takes pictures of the sample at a rate of several images per second.

>> These images are analysed against a predefined library of components that can determine the visible differences between oil, gas and solids.

>> The shape of droplets is a good indicator of an oil and its conditions. For example, oil in ambient conditions is a perfect sphere, while under pressure droplets can change to an egg shape.

>> Gas is a circle with a dark edge and a bright centre. Solids on the other hand have an irregular shape. The software then determines the size and quantity of each object and displays an accurate oil measurement, disregarding unwanted interference from gas and solids.

>> Microscopy is useful because it is easy to calibrate against a specific shape or image and is unaffected by the intensity or wavelength of available light, oil species and solid particle size.

>> Its limitations are associated with cell fouling and optical trauma. The accuracy of microscopy is negatively affected by fouling of the optical monitor (or cell) and by anything that causes an unacceptable level of blurring on the lens. To a large extent, the cell can be kept clean with a minimal maintenance regime.