Heat treatment of cast iron main engine components.

Heat treatment of cast iron main engine components.

Processes, Microstructural Modifications, and Performance Enhancements

1. Introduction

Cast iron, a ferrous alloy characterized by a carbon content exceeding 2% and varying additions of elements such as manganese, silicon, sulfur, and phosphorus, holds a pivotal position in the manufacturing of automotive and mechanical components.1 Its inherent attributes, including exceptional fluidity, a relatively low melting point, superior pouring characteristics, commendable machinability, and notable resistance to wear and deformation, render it an ideal material for crafting intricate engine parts.1 Core engine components, such as cylinder blocks, cylinder heads, pistons, connecting rods, and crankshafts, frequently incorporate cast iron due to its intrinsic strength, prolonged wear resistance, and significant vibration-dampening capabilities, which are particularly critical in heavy-duty applications demanding high durability.2

While cast iron possesses valuable properties in its as-cast state, its full operational potential within the rigorous environment of modern engines is often unlocked through the application of various heat treatment processes. These sophisticated thermal manipulations involve precisely controlled heating and cooling cycles designed to modify the material’s internal microstructure, thereby optimizing its physical and mechanical properties beyond its initial condition.1 The overarching aim of these treatments is to enhance critical performance characteristics, including hardness, tensile strength, yield strength, ductility, impact toughness, wear resistance, and fatigue resistance, ultimately leading to a substantial extension of the service life of vital engine components.7 It is imperative to recognize that the specific type of cast iron (e.g., gray iron, ductile iron, white iron) and its initial microstructure profoundly influence its response to heat treatment, necessitating a careful and informed selection of process parameters.2

The final properties achieved in cast iron are not solely a function of the heat treatment process itself; they are critically dependent on the material’s chemical composition and its initial microstructural state. For instance, the inherent characteristics of cast iron are known to vary based on its composition, the specific heat treatment applied, and the casting process employed.2 This relationship is particularly pronounced in the context of induction hardening, where different types of cast irons, even those with seemingly similar chemical compositions, can exhibit substantially different responses to the same thermal treatment.11 This underscores that a generic application of heat treatment is often insufficient. Instead, a profound metallurgical understanding of the specific cast iron alloy’s chemical makeup is paramount, as it allows metallurgists to accurately predict and control the pathways of microstructural transformation and the resulting mechanical properties. This establishes a direct causal link between the material’s chemistry and the outcomes of process engineering.

Furthermore, the selection of cast iron for engine components, and its subsequent thermal processing, involves a crucial balance of economic and performance considerations. While alternative materials like cast aluminum offer advantages in weight reduction and thermal conductivity, cast iron provides superior strength, wear resistance, and vibration dampening, often at a more favorable cost.3 The subsequent enhancement of cast iron’s mechanical properties through various heat treatments positions it as a highly competitive alternative to more expensive materials, such as forged steel.12 This implies that optimizing cast iron through thermal processing is not merely a technical endeavor but a strategic economic decision for manufacturers, enabling the production of high-performance components while maintaining cost-effectiveness. This balance between technical capability and economic viability is a key driver in the material selection process for engine applications.

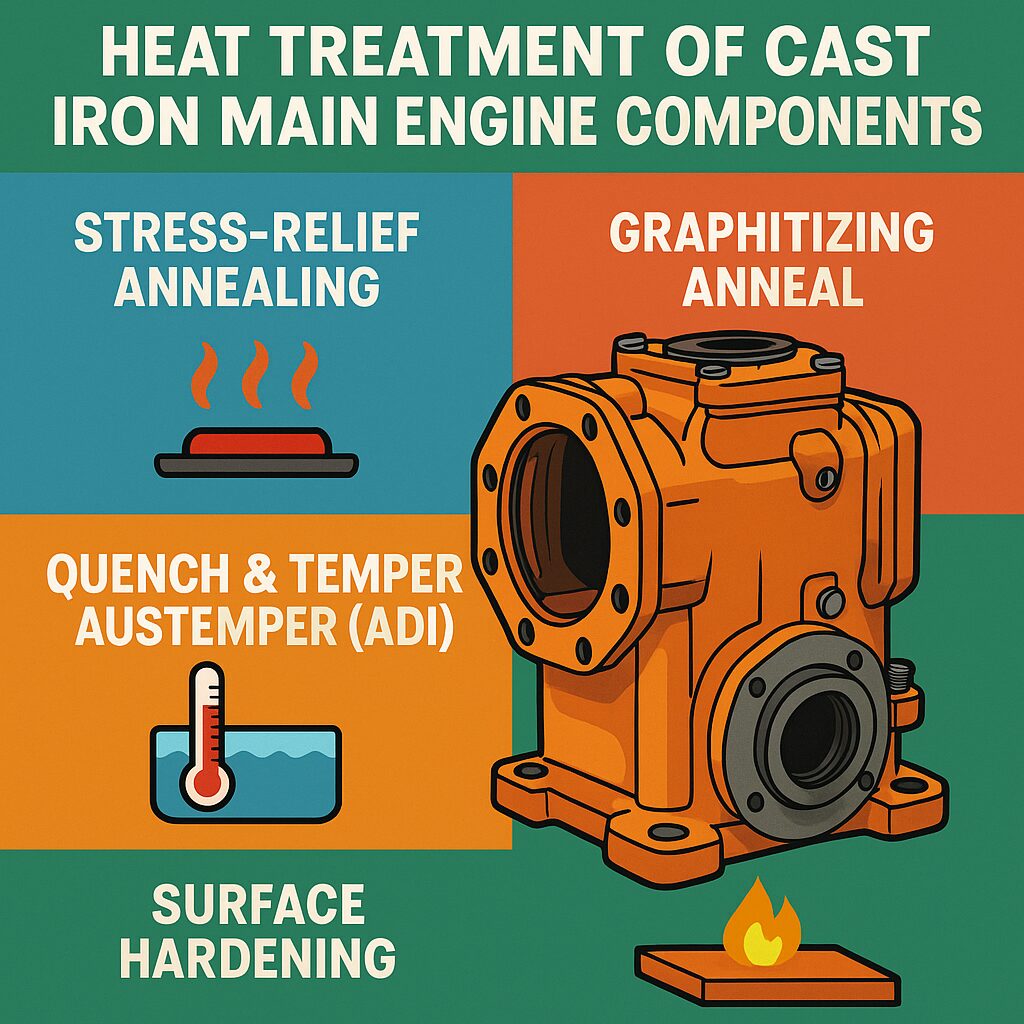

2. Heat treatment processes for cast iron main engine components

This section provides a concise overview and description of the various heat treatment processes commonly applied to cast iron components utilized in main engines, detailing their primary objectives and typical operational parameters.

2.1. Stress Relief

Stress relief is a heat treatment technique specifically designed to mitigate or eliminate internal (residual) stresses that develop within cast iron components during the casting and cooling processes. These stresses frequently arise from non-uniform cooling rates, intricate geometries, or significant variations in cross-sectional areas.1 If left unaddressed, these residual stresses can lead to undesirable distortion, warpage, or even cracking during subsequent machining operations or under operational loads in service.1

The process typically involves heating the cast iron to a constant temperature below its critical transformation temperature, commonly in the range of 550-650°C (1020-1200°F).5 This temperature is maintained for a specific holding duration, followed by a controlled, often slow, cooling back to room temperature.1 The precise time-temperature relationship is critical; excessively high temperatures can inadvertently alter desired mechanical properties, and a protective atmosphere may be required to prevent surface oxidation.5 For castings with intricate shapes, a very gradual cooling, sometimes down to 95°C, is imperative to avoid reintroducing stresses.1 Stress relief is most frequently applied to gray cast irons and ductile cast irons due to their susceptibility to non-uniform cooling during solidification.1

2.2. Annealing

Annealing is a heat treatment process primarily aimed at softening the cast iron material, which significantly enhances its machinability.1 This softening is achieved by altering the material’s microstructure to reduce hardness and concurrently increase its ductility.1 In the specific case of ductile iron, annealing is particularly effective in improving both ductility and impact resistance.5

Annealing cycles vary depending on the desired outcome and the presence of carbides. A common full ferritizing anneal for ductile iron involves heating to 870-900°C (1600-1650°F), holding for approximately 1 hour per inch of section thickness, and then slowly cooling in a furnace at a rate of about 55°C/h (100°F/h) down to 345°C (650°F), followed by air cooling.15 For castings containing eutectic carbides, higher austenitizing temperatures of 900-925°C (1650-1700°F) and longer holding times (minimum 2 hours) are employed, followed by specific furnace cooling rates.15 Subcritical annealing, used to transform pearlite to ferrite, typically involves heating to 705-720°C (1300-1330°F).15 Annealing is widely applied to gray cast irons to improve machinability and to ductile cast irons when maximum ductility and machinability are desired.5

2.3. Normalizing

Normalizing is a heat treatment process applied to iron castings with the primary objective of obtaining a microstructure characterized by fine pearlite. This refined microstructure subsequently leads to increased tensile strength and enhanced wear resistance.5 The process effectively refines the overall grain structure and promotes a more uniform distribution of graphite flakes in gray cast iron or graphite nodules in nodular cast iron.16

The process entails heating the iron to a temperature above its austenitizing temperature, typically ranging from 870-940°C (1600-1725°F) for ductile iron, or approximately 900-950°C for gray cast iron.5 After soaking, the material is cooled in still air.5 The holding time at temperature is generally prescribed as 1 hour per inch of section thickness.15 Normalizing is frequently followed by a tempering step, particularly if the resultant hardness is too high, or to alleviate residual stresses and further enhance toughness.6 This treatment is commonly utilized for ductile iron to boost its strength and wear resistance and to achieve a more consistent and refined microstructure.8 It is less frequently applied to gray cast iron due to a higher risk of distortion and cracking during the heating and cooling phases.17

2.4. Hardening (Quench and Temper)

This is a two-stage heat treatment process designed to achieve the highest possible strength in cast irons.5 The initial “quenching” step involves rapidly cooling the material from a high temperature, which transforms its microstructure into a very hard, yet typically brittle, phase.7 The subsequent “tempering” step is crucial; it involves reheating the quenched material to a lower temperature to reduce this inherent brittleness, relieve internal stresses, and achieve a desirable balance between hardness and toughness.1

For hardening, the cast iron is typically heated to temperatures ranging from 850-925°C 8, or specifically around 870°C for gray cast iron.19 Quenching can be performed using various media such as oil or water, with the choice influencing the cooling rate and final microstructure.7 Tempering is then carried out at a significantly lower temperature range, commonly between 120-595°C 1, or 500-600°C for ductile iron 8, and 150-550°C for gray cast iron.19 Metallurgists must meticulously select and control process parameters to prevent detrimental effects such as distortion, warpage, overheating (burning), or quench cracking.1 This process is primarily employed for ductile cast iron when the highest strength is required.5 It is also applied to high-alloy white irons, where tempering is performed after quenching to temper the as-cast martensitic matrix.1

2.5. Cryogenic Processing

Cryogenic processing is an advanced heat treatment that involves subjecting cast irons to extremely low temperatures. Its primary purpose is to stabilize the material’s microstructure and enhance specific mechanical properties, notably dampening characteristics and wear resistance.5

A typical cryogenic cycle follows a precise thermal profile. It begins with a slow reduction of temperature, typically over 6-8 hours, until the material reaches an extreme low of -195°C (-320°F).5 The material is then stabilized at this cryogenic temperature for an extended period, usually 8-12 hours. Finally, the temperature is slowly raised back to room temperature.5 This process is applied to various types of cast irons to achieve microstructural stability and improve properties such as dampening and wear resistance.5

2.6. Austempering

Austempering is a highly specialized heat treatment process predominantly applied to ductile cast iron, resulting in a material known as Austempered Ductile Iron (ADI). ADI is highly valued for its exceptional combination of high strength, good ductility, superior toughness, and remarkable wear resistance.12 The process involves heating the ductile iron to a temperature where its microstructure transforms entirely into austenite, followed by rapid cooling to an intermediate temperature (above the martensite start temperature) where the austenite then isothermally transforms into a bainitic microstructure.12

The process typically begins with austenitizing the ductile iron at temperatures ranging from 815-927°C for a holding time of 1-2 hours.13 This is followed by rapid quenching to an austempering temperature, usually between 260-400°C, where it is held isothermally for 1-4 hours.13 The cooling rate from the austenitizing temperature must be sufficiently rapid to bypass the formation of undesirable pearlite.12 Austempering is widely employed for ductile iron to achieve a superior balance of mechanical properties, often enabling it to competitively replace more costly forged steel components in demanding applications.12

2.7. Carburizing

Carburizing is a surface hardening thermochemical process where cast iron is exposed to a carbon-rich environment at elevated temperatures.7 This treatment facilitates the diffusion of carbon into the surface layer of the material, significantly increasing its carbon content. The result is the formation of a hard, wear-resistant outer layer, while the core of the component retains its original tough and ductile properties.7

As a diffusion-controlled process, the duration of exposure to the carbon-rich environment directly correlates with the depth of carbon penetration.21 After carburization, the carbon-enriched surface can be further hardened, often through subsequent flame or induction hardening, to achieve the desired surface hardness.7 Carburizing is utilized to enhance surface hardness and wear resistance, particularly in applications where components experience significant friction and abrasion, while simultaneously preserving the toughness of the material’s core.12

2.8. Nitriding

Nitriding is a thermochemical heat treatment process that introduces nitrogen into the surface of ferrous metals, including various types of cast iron.12 This process leads to the formation of a hard, wear-resistant surface layer, commonly referred to as a nitride layer or compound layer.12 This nitride layer significantly enhances the material’s wear resistance, corrosion resistance, and fatigue life.12

Nitriding can be executed through several methods, including salt bath nitrocarburizing, gas nitriding/nitrocarburizing, or plasma nitriding/nitrocarburizing.22 The process typically occurs at temperatures ranging from 400-600°C.22 The presence of nitride-forming alloying elements such as chromium, molybdenum, and aluminum is crucial for the effective formation of stable nitrides.21 A notable advantage of nitriding is that it induces minimal distortion in the component, allowing for it to be performed after final machining.21 Nitriding is employed for components that require exceptionally high surface hardness, superior wear and corrosion resistance, and improved fatigue strength.12

2.9. Induction Hardening

Induction hardening is a localized surface hardening process wherein the surface of a cast iron component is rapidly heated using an electromagnetic induction coil, followed by immediate quenching.11 This rapid heating and cooling cycle produces a hardened surface layer with excellent wear resistance.12

The effectiveness and repeatability of induction hardening are significantly influenced by the matrix carbon content and the specific type of cast iron being treated.11 The process often involves very short heat times, sometimes less than 3 seconds.11 A key benefit of this localized treatment is its ability to minimize overall component distortion.12 Induction hardening is widely applied to various cast irons, including gray, ductile (nodular), malleable, and compacted graphite irons, to enhance their surface hardness and wear resistance in critical applications.11

The consistent emphasis on controlled cooling rates across nearly all heat treatment processes—including stress relief, annealing, normalizing, quenching, austempering, and cryogenic processing—underscores a fundamental principle: the rate of temperature change is as critical, if not more so, than the target temperature itself. This is not merely about reaching a specific thermal setpoint, but about precisely controlling the kinetics of phase transformations within the cast iron. For example, rapid cooling dictates the formation of hard phases like martensite or bainite by suppressing slower transformations such as pearlite formation.18 Conversely, slow cooling allows for the diffusion of carbon and the formation of softer, more ductile phases.15 This precise control over cooling rates directly governs the resulting microstructure, influencing aspects such as the fineness of pearlite, the amount of retained austenite, and the morphology of bainite.16 Consequently, this control directly dictates the final mechanical properties achieved.

Furthermore, the detailed descriptions of these processes reveal that no single heat treatment is universally superior. Instead, each is a specialized tool chosen for a specific purpose, often involving inherent trade-offs between desirable properties. For instance, annealing is explicitly chosen to prioritize machinability and ductility, even when this comes at the expense of hardness.5 Conversely, quenching and tempering are employed to achieve maximum strength, which inherently carries a risk of increased brittleness.5 However, processes like austempering are highlighted for their capacity to achieve a remarkable combination of strength and elongation 13, and an excellent balance of toughness, high strength, decent ductility, and superior wear resistance.18 This indicates a more balanced and versatile property profile for certain advanced treatments. This necessitates that engineers make highly strategic decisions based on the most critical performance requirements for a given engine component, understanding the inherent compromises and synergistic benefits of each process. The selection process thus becomes a multi-objective optimization problem, where various performance metrics must be carefully balanced.

Table 1: Summary of Common Heat Treatment Processes for Cast Iron

| Process Name | Primary Purpose | Typical Temperature Range | Key Microstructural Outcome | Primary Mechanical Property Enhancement |

| Stress Relief | Minimize residual stresses, prevent distortion | 550-650°C (1020-1200°F) | Relaxation of internal lattice strains; no significant phase change | Dimensional stability, reduced cracking risk |

| Annealing | Improve machinability, increase ductility | Full: 870-925°C; Subcritical: 705-720°C | Conversion to ferrite; decomposition of cementite | Reduced hardness, increased ductility & impact resistance, improved machinability |

| Normalizing | Increase tensile strength & wear resistance | 870-950°C (1600-1742°F) | Fine pearlite; refined grain structure; uniform graphite distribution | Increased tensile strength & wear resistance, improved yield strength |

| Hardening (Quench & Temper) | Achieve highest strength & balanced toughness | Quench: 850-925°C; Temper: 120-595°C | Martensite (quenched); tempered martensite/sorbite (tempered) | Significantly increased hardness & strength; balanced toughness |

| Cryogenic Processing | Stabilize microstructure, enhance properties | -195°C (-320°F) | More complete transformation of retained austenite; refined carbides | Enhanced dampening characteristics, improved wear resistance |

| Austempering | Achieve high strength, ductility, toughness, wear resistance | Austenitizing: 815-927°C; Austempering: 260-400°C | Ausferrite (acicular bainitic ferrite + retained austenite) | High strength, good ductility, superior toughness, excellent wear resistance |

| Carburizing | Enhance surface hardness & wear resistance | Elevated temperatures (carbon-rich environment) | Carbon-rich hard surface layer (e.g., martensite); tough core | Enhanced surface hardness & wear resistance; maintained core toughness |

| Nitriding | Increase surface hardness, wear & corrosion resistance, fatigue life | 400-600°C (nitrogen-rich environment) | Hard nitride layer (compound layer); diffusion zone | Increased surface hardness, wear & corrosion resistance, improved fatigue strength |

| Induction Hardening | Localized surface hardening & wear resistance | Rapid heating (localized); immediate quenching | Hardened surface layer (e.g., ringed martensite); maintained core ductility | Enhanced surface hardness & wear resistance; improved fatigue strength; minimal distortion |

3. Microstructural and Mechanical Property Modifications

This section provides a detailed exploration of how various heat treatment processes fundamentally alter the microstructure of cast iron, and in turn, profoundly modify its mechanical properties. The discussion integrates specific microstructural changes with their direct impact on material characteristics for each heat treatment.

3.1. General Principles of Microstructure-Property Relationship in Cast Iron

The macroscopic mechanical properties of cast iron are intrinsically linked to its microscopic microstructure.25 This microstructure typically comprises a complex mixture of phases, predominantly graphite (in various morphologies), ferrite, and pearlite.25 However, depending on the alloy composition and heat treatment, other critical phases such as martensite, bainite, and retained austenite can also be present.13 The morphology, distribution, and volume fraction of these phases, as well as the presence of carbide precipitates and the refinement of grain structure, significantly influence a wide array of properties, including mechanical strength (tensile, yield), hardness, ductility, impact toughness, wear resistance, and fatigue strength.2 For instance, the morphology of graphite can enhance machinability and damping capacity but may concurrently reduce tensile strength and ductility.25 Heat treatment processes are precisely engineered to manipulate these microstructural constituents to tailor the material’s properties for specific, demanding applications.5

Table 2: Comparative Effects of Key Heat Treatments on Cast Iron Properties

| Heat Treatment | Hardness | Tensile Strength | Ductility/Toughness | Wear Resistance | Fatigue Strength |

| Stress Relief | Maintained | Maintained | Maintained | Maintained | Maintained |

| Annealing | Decreased | Reduced | Increased | Decreased | – |

| Normalizing | Increased | Increased | Variable (depends on matrix) | Increased | Increased |

| Quench & Temper | Significantly Increased | Increased | Decreased (Quench), Balanced (Temper) | Increased | Increased |

| Cryogenic Processing | Enhanced | Enhanced | Enhanced | Enhanced | Enhanced |

| Austempering | Increased | Significantly Increased | Significantly Increased | Significantly Increased | Significantly Increased |

| Carburizing | Surface Significantly Increased | Core Maintained | Core Maintained | Significantly Increased | – |

| Nitriding | Surface Significantly Increased | – | Improved | Significantly Increased | Significantly Increased |

| Induction Hardening | Surface Significantly Increased | Increased | Core Maintained | Significantly Increased | Significantly Increased |

3.2. Stress Relief: Microstructure and Properties

Stress relief, by definition, involves heating the material to a temperature below its critical transformation points (subcritical heating). Consequently, this process generally does not induce significant phase transformations or alter the fundamental crystalline structure of the matrix (e.g., pearlitic or ferritic).5 The primary microstructural effect is the relaxation and rearrangement of dislocations within the crystal lattice, leading to a reduction in internal lattice strains. This process effectively reduces the stored elastic energy associated with residual stresses without changing the overall phase composition or graphite morphology. The main mechanical property benefit derived from stress relief is the effective reduction of detrimental residual internal stresses. This reduction is critical for preventing distortion, warpage, and potential cracking of the component during subsequent manufacturing steps (such as machining) or throughout its operational service life.1 Importantly, this process is meticulously controlled to ensure that it does not significantly compromise the material’s existing strength and hardness.5

3.3. Annealing: Microstructure and Properties

Annealing is fundamentally designed to soften the material by inducing specific microstructural transformations. In ductile iron, a full ferritizing anneal achieves this by converting the pearlitic or as-cast matrix entirely to ferrite, with any excess carbon atoms precipitating and depositing onto existing graphite nodules.15 For gray cast iron, annealing can lead to the decomposition of some cementite (iron carbide) into softer ferrite and more stable graphite flakes, thereby refining the overall microstructure.17 The presence of certain alloying elements, such as manganese, phosphorus, chromium, and molybdenum, can impede or retard the kinetics of these annealing transformations.15 The most prominent outcomes of annealing are a substantial reduction in hardness and a notable increase in both ductility and impact resistance.1 This direct softening of the material significantly improves its machinability, making subsequent manufacturing operations easier and more efficient.1 While annealing enhances machinability and ductility, it is important to note that it may concurrently lead to a reduction in the material’s overall hardness and wear resistance.17 Additionally, annealing contributes to the reduction of internal stresses, which makes the material less susceptible to cracking under tensile loads.7

3.4. Normalizing: Microstructure and Properties

The primary microstructural objective of normalizing is to achieve a fine pearlitic matrix.5 This process refines the overall grain structure of the cast iron and promotes a more uniform and homogeneous distribution of graphite nodules (in nodular cast iron) or graphite flakes (in gray cast iron) within the matrix.16 The specific normalizing temperature plays a critical role in determining the final matrix composition: higher temperatures tend to favor the formation of a pearlitic matrix, while lower temperatures encourage a more ferritic matrix.16 Normalizing can also facilitate the dissolution of undesirable carbides present in the as-cast matrix.16 Normalizing effectively increases both the tensile strength and wear resistance of the cast iron.5 It can also lead to an improvement in yield strength.16 The hardness of the cast iron generally increases with higher normalizing temperatures, particularly as the matrix shifts towards a pearlitic structure, thereby offering improved wear resistance.16 The impact on ductility is dependent on the resulting matrix: a ferritic matrix (formed at lower temperatures) typically exhibits higher ductility, whereas a pearlitic matrix (formed at higher temperatures) can lead to a reduction in ductility due to pearlite’s inherent characteristics.16 Furthermore, a uniform distribution of refined graphite nodules and a more homogeneous matrix contribute to improved impact toughness.16 Notably, normalized structures are well-conditioned to respond effectively to subsequent induction hardening treatments.5

3.5. Hardening (Quench and Temper): Microstructure and Properties

The quenching step involves rapid cooling, which causes a diffusionless transformation of the high-temperature austenite phase into a very hard, yet inherently brittle, martensitic structure.7 Martensite is characterized as a supersaturated solid solution of carbon atoms trapped within a body-centered tetragonal (BCT) crystal structure, leading to a highly distorted lattice that is the primary reason for its exceptional hardness.19 Water quenching typically results in a very hard and often non-uniform martensitic structure, whereas oil quenching, with its slower and more uniform cooling rate, can allow for the partial formation of graphite and pearlite within the microstructure.19 Subsequent tempering then modifies the as-quenched martensite, changing the character of tempered structures from bainite to sorbite, and can lead to the conversion of most graphite flakes into a needle-like martensitic structure.19 Tempering also plays a crucial role in reducing the amount of retained austenite.9

Quenching alone significantly boosts the hardness of cast iron 7, with reported increases of up to 100% for gray cast iron.19 However, this dramatic increase in hardness comes with a substantial trade-off: a significant increase in brittleness.7 Tempering is therefore a critical follow-up step, essential for mitigating this brittleness, achieving a balanced combination of hardness and toughness, and preventing the formation of cracks.7 Tempering can also lead to an increase in overall strength, particularly tensile strength.7 Specific optimal tempering temperatures can be chosen to achieve good wear resistance.19 It is observed that the hardness of hardened gray cast iron is marginally higher compared to hardened and tempered gray cast iron, a slight reduction attributed to the presence of internal discontinuities caused by the distribution of graphite flakes within the matrix.19 This recurring theme concerning hardening processes, where high hardness is often desired for wear resistance but the formation of very hard phases like martensite can render the material susceptible to brittle fracture, highlights a fundamental metallurgical challenge. Tempering is consistently presented as an indispensable follow-up step that is critical for mitigating this brittleness, achieving a balanced combination of hardness and toughness, and effectively relieving internal stresses.7 This emphasizes a fundamental metallurgical challenge that necessitates precise control and often multi-step processing to achieve optimal performance without compromising the component’s structural integrity.

3.6. Cryogenic Processing: Microstructure and Properties

Cryogenic treatment, involving exposure to extremely low temperatures (e.g., -195°C / -320°F), primarily functions to stabilize the microstructure of cast iron.5 While specific phase transformations are not detailed, the process is understood to promote the more complete transformation of retained austenite (a softer phase) into martensite, and to refine and more uniformly distribute carbide precipitates. These changes lead to a more stable, homogeneous, and refined internal structure within the material. This microstructural stabilization and refinement directly contribute to enhanced mechanical properties, particularly improving dampening characteristics and wear resistance.5 The overall performance of the cast iron is improved by this refinement of its internal structure.5

3.7. Austempering: Microstructure and Properties

Austempering induces a unique microstructural transformation, converting austenite into a distinctive ausferritic structure. This ausferrite is a two-phase mixture primarily composed of acicular bainitic ferrite and carbon-saturated retained austenite.12 The morphology of the ferrite can vary from needle-like to feather-like, depending on the specific austempering temperature, with higher temperatures generally leading to coarser microstructures.18 Retained austenite can exist in two forms: easily identifiable blocky austenite and finer, filmy austenite distributed among the acicular ferrite; the volume of blocky austenite tends to increase with higher austempering temperatures.18 The presence of specific alloying elements (e.g., Silicon, Nickel, Molybdenum, Copper) is crucial as they help to stabilize and preserve the carbon-enriched retained austenite by inhibiting the formation of undesirable pearlite during the austempering process.18 However, if the carbon-saturated austenite undergoes further breakdown, it can lead to the precipitation of carbides, which may detrimentally affect hardness and strength.18

Austempered Ductile Iron (ADI) is renowned for achieving an exceptional balance of mechanical properties: high strength (typically 1000-1500 MPa), decent ductility (4-12%), excellent toughness (50-60 joules), and superior wear resistance.12 Generally, lower austempering temperatures result in finer microstructures, which correlate with higher hardness and increased tensile strength.18 Conversely, as the quantity of retained austenite increases, the impact energy of the material also tends to rise.18 The unique presence of graphite nodules within the ADI matrix can act as a dry lubricant, effectively lowering the coefficient of friction and reducing wear loss.18 Furthermore, superior wear resistance in ADI is often linked to a combination of high surface hardness and the phenomenon of stress-induced transformation of retained austenite into martensite (known as the TRIP effect).18

The role of retained austenite is critical and highly significant, particularly in advanced heat treatments such as austempering. Its presence, stability, and its unique ability to transform under mechanical stress (the Transformation-Induced Plasticity, or TRIP effect) are directly linked to achieving a desirable balance of high strength, improved ductility, and enhanced impact toughness.13 While higher quantities of retained austenite can, in some cases, be associated with reduced hardness and strength at elevated austempering temperatures, an increase in its quantity is also observed to elevate impact energy.18 The precise control over the volume fraction and carbon content of retained austenite represents a key metallurgical challenge and a significant opportunity for optimizing the overall mechanical properties of cast iron, allowing for a combination of properties that might otherwise be mutually exclusive. This demonstrates that the behavior of this specific phase is engineered to achieve specific performance goals.

3.8. Carburizing: Microstructure and Properties

Carburizing fundamentally alters the surface chemistry of cast iron by increasing the carbon content in the outer layer.7 This carbon enrichment, followed by appropriate cooling, leads to the formation of a hard, carbon-rich outer layer, typically martensitic after quenching, while the core of the component largely retains its original tough and ductile microstructure.7 The depth of this hardened layer is a function of the diffusion time in the carbon-rich environment.21 The primary benefits of carburizing are a significant enhancement in surface hardness (e.g., 600-800 HV for carburized nodular cast iron compared to 200-300 HV for non-carburized) and a marked improvement in wear resistance.7 Crucially, this surface hardening is achieved while maintaining the high toughness of the material’s core, providing a desirable combination of properties for applications requiring both surface durability and structural integrity.12

3.9. Nitriding: Microstructure and Properties

Nitriding introduces nitrogen atoms into the surface of the cast iron, leading to the formation of a hard, wear-resistant nitride layer, also known as the compound layer (composed of iron nitrides like γ’ Fe4N or ε-phase Fe3N), and a diffusion zone beneath it.12 The diffusion zone contains nitrogen in solid solution and stable metal nitrides formed by alloying elements (e.g., aluminum, molybdenum, chromium, tungsten).22 The hardness of the compound layer is directly influenced by the content of nitride-forming alloying elements.22 Nitriding significantly increases surface hardness (e.g., 300-400 HV for carbon steels, and over 700-1000 HV for alloyed steels, with similar substantial increases for cast iron).12 This process greatly enhances wear resistance, corrosion resistance, and improves the fatigue strength of the material.12 A key advantage of nitriding is that it induces minimal distortion in the component, making it suitable for treatment after final machining operations.21

3.10. Induction Hardening: Microstructure and Properties

The rapid heating and subsequent quenching during induction hardening result in the formation of a hardened surface layer.12 In ferritic ductile irons, the short-distance carbon diffusion that occurs during the rapid heating phase leads to the formation of distinctive ringed martensite structures surrounding the graphite nodules.11 The typical as-hardened microstructure achieved through this process comprises a two-phase structure of fine-grain martensite and nodular graphite, with a minimal and often desirable amount of retained austenite.24 Induction hardening significantly enhances surface hardness (e.g., 700-900 HV for induction hardened nodular cast iron compared to 200-300 HV for non-hardened) and substantially improves wear resistance.11 It can also noticeably improve the fatigue strength of ferritic ductile irons, a benefit attributed to the formation of ringed martensite and the favorable distribution and magnitude of compressive residual stresses induced by the process.11 Importantly, induction hardening is a localized treatment that maintains the core ductility of the component 12 and minimizes overall distortion.11

The detailed descriptions of carburizing, nitriding, and induction hardening highlight a sophisticated shift in metallurgical strategy: moving beyond merely modifying bulk material properties to implementing targeted surface engineering for specific performance enhancements.11 These processes are designed to create a hard, wear-resistant surface layer while deliberately preserving a tough and ductile core. This approach is critically important for engine components that are subjected to significant friction, abrasion, and localized stresses, such as gears, shafts, and cylinder liners. This indicates a highly refined understanding of localized property requirements and the ability to selectively modify material characteristics precisely where needed, thereby optimizing for both surface durability and the overall structural integrity of the component. This represents a higher level of material design, focusing on functional gradients within the material.

4. Enhancing Wear Resistance, Strength, and Service Life in Main Engine Parts: Examples

This section provides concrete examples illustrating how specific heat treatment processes are applied to various cast iron main engine components to significantly improve their wear resistance, strength, and overall service life, linking the theoretical aspects to practical engineering outcomes.

4.1. Cylinder Liners

Cylinder liners are indispensable components within internal combustion (IC) engines, serving as the inner surface against which the piston reciprocates. They must withstand extremely harsh operating conditions, including high temperatures, intense friction, and severe abrasive and adhesive wear.4 These liners are frequently manufactured from alloy cast iron specifically for its wear resistance.4

Advanced heat treatment processes, involving precise rapid cooling (e.g., at a rate of 14.5–23.3 °C/s) followed by controlled tempering (e.g., at 480–520 °C), are designed to induce the formation of bainitic microstructures in low-alloy cylinder liners.9 This transformation significantly enhances the material’s hardness, tensile strength, and critically, its wear resistance.9 For instance, low-alloy cast bainite cylinder liners have demonstrated a remarkably low total average wear loss of 0.014 mm, which is a substantial improvement compared to 0.044 mm for boron cast iron liners.9 This superior wear performance is attributed to the high density of dislocations and the unique dislocation substructure present within the retained austenite, which effectively restricts dislocation movement, along with a solid solution strengthening effect from carbon atoms diffusing into the ferrite matrix.9 The overall effect is a significant improvement in the reliability and service life of IC engines.9

Cylinder liners can also benefit from induction hardening. This process is applied to gray iron cylinder liners for commercial vehicle engines, leading to improved wear resistance and strength.11 The formation of ringed martensite around graphite nodules in ferritic ductile irons, resulting from short-distance carbon diffusion during rapid heating, contributes to a localized hardness increase and an associated increase in strength, which directly enhances wear resistance.11

4.2. Connecting Rods

Connecting rods are critical engine components that convert the reciprocating motion of the piston into the rotational motion of the crankshaft.4 They are subjected to high cyclic loading, demanding exceptional strength, ductility, and fatigue resistance.

Austempering (ADI) and Quenching and Partitioning (Q&P) heat treatments are particularly effective in enhancing the mechanical properties of ductile cast iron connecting rods for automotive applications.13 These treatments lead to the formation of specific microstructures that provide a superior balance of properties. For ADI, the microstructure primarily consists of carbide-free bainite with stabilized retained austenite.13 The Q&P process, on the other hand, yields a mixed microstructure of low carbon martensite, carbon-partitioned stabilized austenite, and carbide-free bainite, often resulting in properties comparable to or even superior to ADI.13 These microstructures contribute to significantly improved tensile strength, ductility, and fatigue strength.13 For example, the Q&P process applied to ductile iron connecting rods has been shown to result in an approximate 17% increase in tensile strength and 16% in hardness compared to conventional ADI.13 The presence of retained austenite in these structures can also exhibit Transformation Induced Plasticity (TRIP), where mechanical deformation transforms austenite into martensite, providing good work hardening without compromising ductility.13 This combination of properties makes ADI a promising engineering material, offering a good balance of low cost, design flexibility, high strength-to-weight ratio, good toughness, and wear resistance, thereby extending the service life of connecting rods.13

4.3. Gears

Gears in engine systems are subjected to immense contact stresses, bending stresses, and continuous friction, necessitating high surface hardness for wear resistance and a tough core to withstand impact and fatigue loads.12

Carburizing is an effective heat treatment for cast iron gears. By exposing the gear surface to a carbon-rich environment at high temperatures, a hard, wear-resistant outer layer is formed, while the core maintains its toughness and ductility.12 This significantly enhances surface hardness (e.g., 600-800 HV for carburized nodular cast iron compared to 200-300 HV for non-carburized), leading to improved wear resistance.12 This allows gears to withstand prolonged abrasive wear and maintain their precise tooth profiles, extending their operational life.

Nitriding is another thermochemical process applied to cast iron gears to enhance their performance.22 The introduction of nitrogen into the surface creates a hard nitride layer, which significantly increases surface hardness, wear resistance, and fatigue strength.12 This is particularly beneficial for gears that experience high contact pressures and cyclic loading, as the improved surface properties prevent pitting and scuffing, leading to a longer service life.

Induction hardening is also widely applied to cast iron gears. This localized surface hardening process creates a hardened surface layer with excellent wear resistance while maintaining the core ductility.12 For example, induction hardened nodular cast iron can achieve surface hardness values of 700-900 HV, significantly higher than non-hardened material.12 This targeted hardening minimizes distortion, making it suitable for precision components like gears, and contributes to their extended service life by resisting wear and fatigue.12

Austempered Ductile Iron (ADI) is increasingly used for gears in transmission systems and planetary gear units.14 The ausferritic microstructure of ADI provides a combination of high strength, toughness, and excellent wear resistance.12 This allows ADI gears to handle high loads and resist wear effectively, contributing to the durability and extended service life of the entire transmission system.12

4.4. Camshafts and Crankshafts

Camshafts and crankshafts are fundamental engine components responsible for converting motion and transmitting power. Camshafts control valve timing, while crankshafts convert the linear motion of pistons into rotational motion.4 Both are subjected to significant bending, torsional, and fatigue stresses, as well as surface wear in bearing and journal areas.10

Induction hardening is a widely adopted heat treatment for cast iron camshafts and crankshafts.11 This process creates a hardened surface layer, significantly improving wear resistance in critical areas such as cam lobes and bearing journals.11 The formation of ringed martensite around graphite nodules in ductile irons, combined with favorable compressive residual stresses, contributes to noticeably improved fatigue strength.11 Advanced induction hardening technologies can achieve almost undetectable camshaft distortion (approximately 3 to 5 microns), which eliminates the need for subsequent straightening operations, enhancing manufacturing efficiency and component quality, and directly contributing to a longer service life.11

Nitriding is also applied to camshafts and crankshafts in high-performance motors.22 This process forms a hard, wear-resistant nitride layer on the surface, which improves fatigue strength and corrosion resistance.12 The ability of the porous nitride layer to retain lubricants further enhances the running properties of components like camshafts, leading to reduced friction and extended operational life.22

For cast iron crankshafts, stress relief is crucial to manage internal stresses from casting and prevent distortion or cracking during machining or service.10 In cases of localized overheating due to bearing failure, controlled annealing can be applied to restore the material’s original properties by relieving excessive hardness caused by uncontrolled quenching.26 This careful thermal management ensures the crankshaft can endure repeated forces without premature failure, extending its fatigue life and overall service life.10

Austempered Ductile Iron (ADI) is also utilized for crankshafts, particularly in off-road vehicles.14 The excellent combination of high strength, abrasion resistance, and toughness offered by ADI makes it a suitable material for crankshafts, which must withstand high loads and provide long-term durability.12

5. Conclusion

The performance and longevity of cast iron main engine components are profoundly influenced by meticulously controlled heat treatment processes. These thermal manipulations are not merely supplementary steps in manufacturing but are fundamental to tailoring the material’s microstructure to meet the rigorous demands of engine operation.

The various heat treatments—including stress relief, annealing, normalizing, hardening (quench and temper), cryogenic processing, austempering, carburizing, nitriding, and induction hardening—each serve distinct purposes. They range from mitigating residual stresses and enhancing machinability to achieving exceptional hardness, strength, ductility, and wear resistance. A critical understanding that emerges from this analysis is the paramount importance of precisely controlling cooling rates during these processes. The kinetics of phase transformations, which are directly governed by these rates, dictate the final microstructural constituents and their morphology, thereby profoundly influencing the macroscopic mechanical properties.

Furthermore, the selection of a specific heat treatment is a strategic decision that involves balancing various desirable properties, often with inherent trade-offs. While some treatments prioritize a single property, advanced processes like austempering demonstrate the capability to achieve a synergistic combination of high strength, ductility, toughness, and wear resistance. This multi-objective optimization highlights the sophisticated nature of metallurgical engineering in achieving optimal performance. The recurring significance of retained austenite in advanced treatments, and its engineered transformation under stress, exemplifies how specific microstructural phases are manipulated to achieve otherwise mutually exclusive property combinations.

Beyond bulk property modification, the application of surface engineering techniques such as carburizing, nitriding, and induction hardening represents a refined metallurgical strategy. These processes selectively harden the surface for superior wear and fatigue resistance while preserving the inherent toughness and ductility of the component’s core. This targeted approach is crucial for engine parts subjected to localized stresses and friction, demonstrating a highly evolved understanding of functional gradients within materials.

In practical applications, these heat treatments demonstrably enhance the service life of critical engine components. For cylinder liners, bainitic transformations and induction hardening significantly reduce wear. Connecting rods benefit from austempering and Q&P processes, which provide superior strength and fatigue resistance. Gears achieve enhanced surface hardness and wear resistance through carburizing, nitriding, and induction hardening. Similarly, camshafts and crankshafts gain improved wear resistance and fatigue strength from induction hardening and nitriding, often with minimized distortion.

In essence, the strategic application of heat treatment transforms cast iron from a capable material into a high-performance alloy, capable of withstanding the extreme conditions within modern engines. The intricate relationship between processing parameters, microstructural evolution, and the resulting mechanical properties underscores the continuous advancement in materials science and engineering, driving the development of more durable, efficient, and reliable engine systems.

Works cited

1. Information on the Heat Treatment of Cast Irons – Alpha Detroit, accessed June 24, 2025, https://alphadetroit.com.au/information-on-the-heat-treatment-of-cast-irons/

2. The Properties of Cast Iron Explained, accessed June 24, 2025, https://www.castironwelding.co.uk/blog/what-are-the-properties-of-cast-iron/

3. Cast Aluminum vs Cast Iron Engine Parts: Understanding Material Differences, accessed June 24, 2025, https://stahlspecialty.com/cast-aluminum-vs-cast-iron-engine-parts/

4. 4 engine block | PPT – SlideShare, accessed June 24, 2025, https://www.slideshare.net/slideshow/4-engine-block/77656414

5. How heat treatment helps your iron casting perform its best – The …, accessed June 24, 2025, https://calawton.com/heat-treatment-iron-castings/

6. Types of Heat Treatment for Cast Iron – Dandong Foundry, accessed June 24, 2025, https://www.iron-foundry.com/types-of-heat-treatment-for-cast-iron.html

7. How Heat Treatment Improves the Strength of Iron Castings – Sinoway Industry Metal Parts, accessed June 24, 2025, https://sinowayindustry.com/how-heat-treatment-improves-the-strength-of-iron-castings/

8. Heat Treatment of Ductile Cast Iron: Why It Matters? – RM Technocast, accessed June 24, 2025, https://www.rmtechnocast.com/heat-treatment-of-ductile-cast-iron/

9. Effects of Heat Treatment on Microstructures and Mechanical … – MDPI, accessed June 24, 2025, https://www.mdpi.com/1996-1944/17/4/802

10. What is the importance of proper heat treatment in steel crankshaft manufacturing?, accessed June 24, 2025, https://www.jswonemsme.com/blogs/blogs-articles/what-is-the-importance-of-proper-heat-treatment-in-steel-crankshaft

11. Induction hardening of cast irons | Thermal Processing Magazine, accessed June 24, 2025, https://thermalprocessing.com/induction-hardening-of-cast-irons/

12. Enhancing Wear Resistance of Nodular Cast Iron through Advanced …, accessed June 24, 2025, https://www.zhycasting.com/enhancing-wear-resistance-of-nodular-cast-iron-through-advanced-heat-treatment-techniques/

13. (PDF) Enhancing Mechanical Properties of Ductile Cast Iron …, accessed June 24, 2025,https://www.researchgate.net/publication/315677151_Enhancing_Mechanical_Properties_of_Ductile_Cast_Iron_Conrods_through_Different_Heat_Treatments

14. Austempered Ductile Iron | Aalberts Surface Technologies, accessed June 24, 2025, https://aalberts-ht.us/austempering/

15. heat treating of nodular irons 2 | Total Materia, accessed June 24, 2025, https://www.totalmateria.com/en-us/articles/heat-treating-of-nodular-irons-2/

16. Effect of normalizing temperature on properties and microstructure of …, accessed June 24, 2025, https://www.zhycasting.com/effect-of-normalizing-temperature-on-properties-and-microstructure-of-nodular-cast-iron/

17. Heat Treatment Techniques for Enhancing Grey Cast Iron’s Performance, accessed June 24, 2025, https://www.zhycasting.com/heat-treatment-techniques-for-enhancing-grey-cast-irons-performance/

18. A Review on Heat Treatment of Cast Iron: Phase Evolution and …, accessed June 24, 2025, https://www.mdpi.com/1996-1944/15/20/7109

19. Processing and Effect of Heat treatment on Mechanical Properties of …, accessed June 24, 2025, https://www.ijert.org/research/processing-and-effect-of-heat-treatment-on-mechanical-properties-of-gray-cast-iron-IJERTV5IS090571.pdf

20. Austempered ductile irons ADI – Zanardi Fonderie SpA, accessed June 24, 2025, https://zanardifonderie.com/en/academy/the-basics-of-the-austempering-process/austempered-ductile-irons-adi/

21. Case-hardening – Wikipedia, accessed June 24, 2025, https://en.wikipedia.org/wiki/Case-hardening

22. Notes Application – Struers.com, accessed June 24, 2025, https://www.struers.com/-/media/Library/Brochures/English/Application-Note-Nitrided-Coatings.pdf

23. Metallography of nitrided and nitrocarburized parts | Struers.com, accessed June 24, 2025, https://www.struers.com/en/Knowledge/Materials/Nitrided-coatings

24. Induction hardening of cast irons – Inductotherm Group, accessed June 24, 2025, https://inductothermgroup.com/induction-hardening-of-cast-irons/

25. Advanced Cast Iron – Number Analytics, accessed June 24, 2025, https://www.numberanalytics.com/blog/advanced-cast-iron

26. Crankshaft Annealing | In-Situ Annealing – Goltens, accessed June 24, 2025, https://www.goltens.com/services/in-place-machining-experts/crankshaft-annealing/